The handbook is crammed with charts, tables, diagrams, nomographs

and formulas, photographs and examples of conveyor installations.

Covered in the book are standards, terms and conditions, definitions,

equipment specs for procurement, material classifications and

plant layout.

Other sections on BELT CONVEYORS cover application

limitations, angles of incline, belt widths, speeds and conveyor

capacities, belt tension and HP requirements, acceleration and

braking forces, belting grades and construction, idlers and pulleys,

loading and discharging the belt, conveyor drives and drive location

and arrangements.

The section one CHAIN CONVEYORS includes chain types,

attachments, chain metals and other chain considerations, notes

on operations and maintenance, chain selection criteria, spokesperson,

drag scraper and flight conveyors, layout and arrangement, capacity

and required power.

Professionals will find this handbook an invaluable, easily accessible

resource containing everything needed to specify, purchase and

maintain bulk solid conveyor systems.

Click Here to download a pdf copy of the Bulk Conveyor Reference Book

Table of Contents and Index

ROTARY FEEDERS - Move Dry Varied Shape Materials

SOME OF OUR CUSTOMERS

MATERIAL HANDLING SINCE 1905

MATERIAL HANDLING FOR THE 21st CENTURY

Vancouver Wedding Photos

FROM BEAUMONT BIRCH

FROM BEAUMONT BIRCH

Coal Discharger Valve

The FIRST Major Innovation In 'Mass Flow' Technology in 30 Years

Industrial Weigh Belt Feeders

Beaumont Acquires Material Sampling Manufacturer

MANUFACTURERS'S AGENTS WANTED

We have been designing and building bulk solids handling equipment since 1904.

We are currently seeking additional representation in many areas throughout the

U.S. and other countries throughout the world. If bulk handling equipment

would compliment your existing lines, please contact us by completing our

Agency Information Form.

Beaumont Birch manufactures a complete line of rotary feeders

available in outlet sizes from 2 to 16 inches. Various models

available for low, medium and high differential pressures.

The company specializes in Waste Treatment Bulk Material Movement;

Coal, Ash, Gravel & Sand Bulk Handling Conveyors of every

type. We also manufacture a line of Rotary Feeders in sizes from

2"to 16" diameter that operate at high temperature and

pressure.

SOME OF OUR CUSTOMERS

|

General Motors Corporation

Ogden Martin Systems,Inc.

Wheelabrator Technologies

RMerck & Company

Mobile Oil Company

FMC Corporation

Commonwealth of Pennsylvania

Chrysler Corporation

International Paper Company

Occidental Chemical Corporation

Exxon Corporation

Nigerian Petroleum Company

Tennessee River Pulp & Paper

|

|

Fuller Company

Brown & Williamson Tobacco Company

Dow Chemical Company

Westinghouse Corporation

Allied Chemical Corporation

Burlington Industries

General Electric Corporation

Stone Container Corporation

Mead Paper

Champion Paper

Foster Wheeler Corporation

|

|

|

Southeastern Public Service

Ciba Geigy

American Ref-Fuel Corporation

Asea, Brown,Boveri

Buick Motor Company

Ford Motor Company

Morton Salt

Amoco Oil Corporation

Amoco Chemical Corporation

Van Roll Corporation

Cargill Corporation

Bechtel Corporation

M.W. Kellogg Company

McBurney Corporation

Longview Fiber Company

|

THIS DOMAIN NAME AND/OR WEBSITE ARE FOR SALE

along with a customized conveyor marketing plan containing a database of 1000+ former customers and 15000+ prospects in the following industries:

|

1544 Sugar Refineries

1931 Concrete Manufacturing

2300 General Warehousing

981 Coal Mining

1714 Chemical Manufacturers

2236 Paper Mills

662 Petroleum Refineries

|

94 Bottling Plants

46 Iron Mining

45 Copper Mining

923 Food Processing Plants

2158 Airport Facilities

652 Coal Power Plants

|

MATERIAL HANDLING CIRCA: 1905...

The year was 1905, President Theodore Roosevelt had

just begun his second term. Beaumont Company was already known

for bulk handling equipment designed by it's world famous founder

and engineer R.H. Beaumont.

1905 was also the year that congress discontinued gold dollar

coinage minted in Philadelphia since 1849. The Southern Warehouse

Company, one of the temporary storage facilities under contract

to the federal government, needed a bulk handling system capable

of rapidly moving large quantities of heavy materials.

In just 98 days Beaumont designed, built and erected a unique

gravity operated system that would handle 2000 barrels a day,

each weighing 580 lbs. The barrels rode down a 22"wide track

cradled in wooden trolley with 4 eight inch diameter flanged wheels.

After unloading each trolley returned up to the loading platform

on rails below the loaded barrels.

MATERIAL HANDLING FOR

THE 21st CENTURY...

Today, the Beaumont Birch Company carries on R.H. Beaumont's

early tradition of "getting the job done on time to the most

stringent specifications ". Our technical staff is ready

for the next century... They are equipped to handle estimating,

design and production of every type bulk material handling problem.

Our staff has expertise in electrical, mechanical and structural

engineering and manufacturing. Our 100,000 sq. ft. facility in

Pennsauken NJ, the company maintains a complete major equipment

center including a machine shop, sheet metal shop and welding

shop. Each shop is equipped with full overhead crane service.

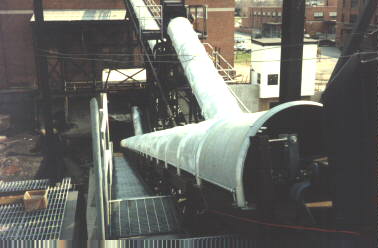

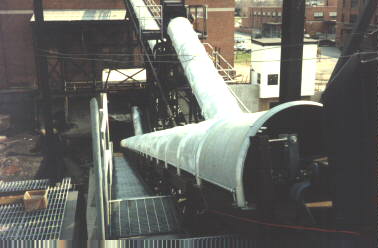

COAL, ASH & WASTE DISPOSAL CONVEYORS

Beamont Birch Company fabricates custom built bulk handling conveyor

systems for waste disposal and material handling of coal, lignite,

wood and trash for companies and municipalities that produce electrical

power.

Southeastern Public Service Authority of Virginia operated a refuse

and coal combustion facility since 1987 to generate steam and

electricity for the Norfolk Naval Ship yard with only ONE CONSTANT

HEADACHE: ASH HANDLING. Beaumont Birch designed, manufactured

and installed four submerged wet drag conveyors for bottom ash,

siftings and truck load out; as well as screw conveyors for boiler

and economizer fly ash. Our company also modified the stand-by

drag conveyor and several fly ash conveyors to permit discharge

into a new ash conditioning system. Lane Brown, Plant Manager

of Southeastern Public Service Authority has stated, "The

new ash handling system has improved reliability, reduced hauling

and maintenance costs and increased cleanliness at the plant".

Click Here to download a pdf copy of the Bulk Conveyor Reference Book

Table of Contents and Index

- Go to the top

Click on Logo for a FREE Industrial Trade Show Booth For Your Company

FROM BEAUMONT BIRCH

FROM BEAUMONT BIRCH